Turning industrial component challenges into working innovations through high-tech additive manufacturing and material science are what drives us every day.

We realize complex innovations by multidisciplinary projects based on our key areas of expertise ensuring the highest quality standards and component reliability.

A new optimization world is now within reach.

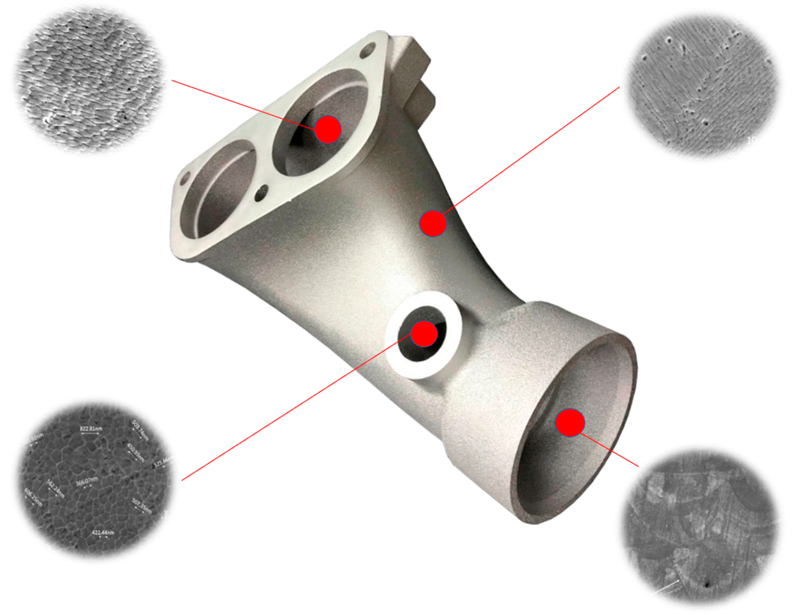

AENIUM “Multivolume variable LASER energy density” [MVLED] method allows us to program the desired part microstructures and increases close-inert porosity over certain volumes of the part. Depending on the metallurgy alloy, our energy LASER algorithms allow us to achieve variation into different volumes, surfaces or shells into the same part, having a disruptive precise control over different material properties before heat treatment, HIP and postprocessing. Some of the achievements with [MVLED] :

Tailoring LASER energy density we are able to improve your components through the most complex AM approach to material engineering applied to your parts.

Imagine a unique part with some high conductive thermal volumes and thermal bridge breaking over complex shells as a heat flux guideline manufactured in the same material all over it. Thermal/electrical insulating and conductive behaviours over the same part through additive manufacturing.

Contact us for exploring how [MVLED] can improve your products and components.

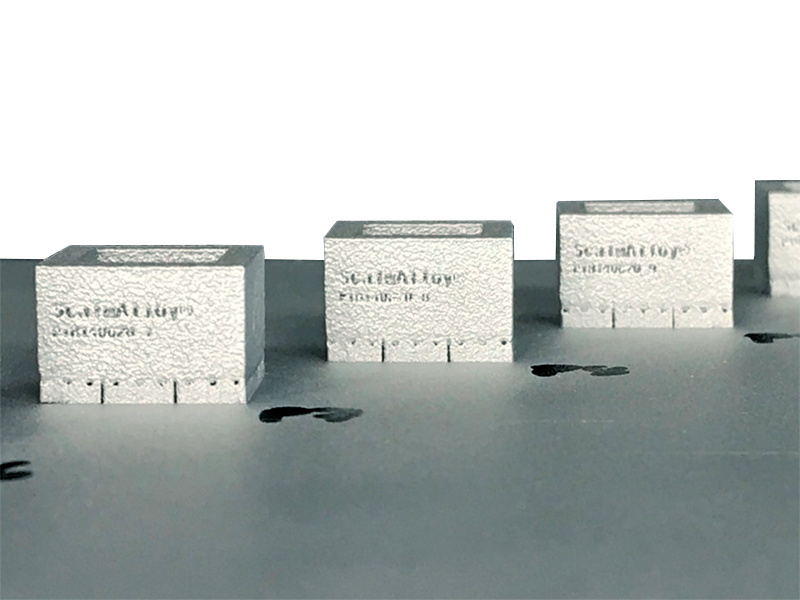

Material requirements are commonly one of the critical barriers on common additive manufacturing. Certified solutions are needed for ensuring part performance following UE / US or other technical standards for each field and certification.

AENIUM R&D team formed by material focused engineers and experts can support your application to develope and industrialise components from TRL1-2 to TRL9 in record time achieving full NADCAP qualification.

Our material portfolio based on qualified materials for industrial needs provided:

The material processing and performance is not an AM problem anymore.

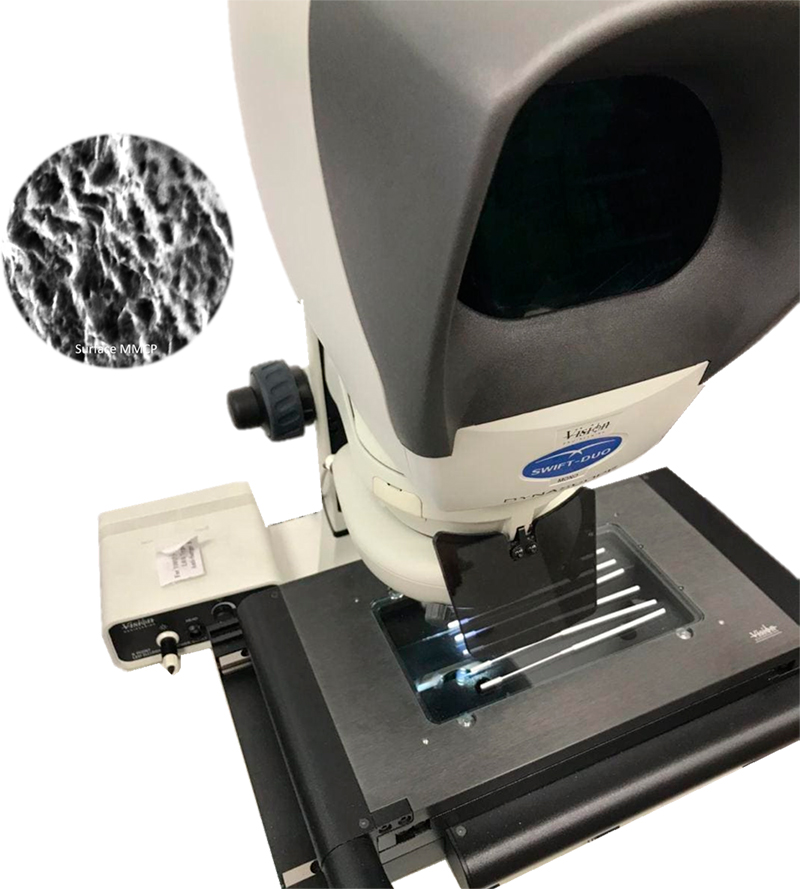

Following our extended experience researching over material science and LASER melting, our DMLS / SLS team works over LASER parameter for achieving high-performance results and avoiding crevice defects, internal stress concentration resulting the highest mechanical properties and microstructure desired.

Qualified materials for industrial needs provided:

Every parameter series is developed for a full qualification AM procedure including postprocessing parameters. We´re able to industrialise under Helium, Argon and Nitrogen atmospheres.

AENIUM ENGINEERING S.L. has been a beneficiary of the European Regional Development Fund whose objective is to improve the competitiveness of SMEs and thanks to which it has launched an Action Plan with the aim of improving its positioning in foreign markets through the implementation of innovative solutions during the year 2021. For this, it has had the support of the InnoXport Program of the Chamber of Commerce of Valladolid and the Provincial Council of Valladolid.