MOST ADVANCED INDUSTRIAL EQUIPMENT

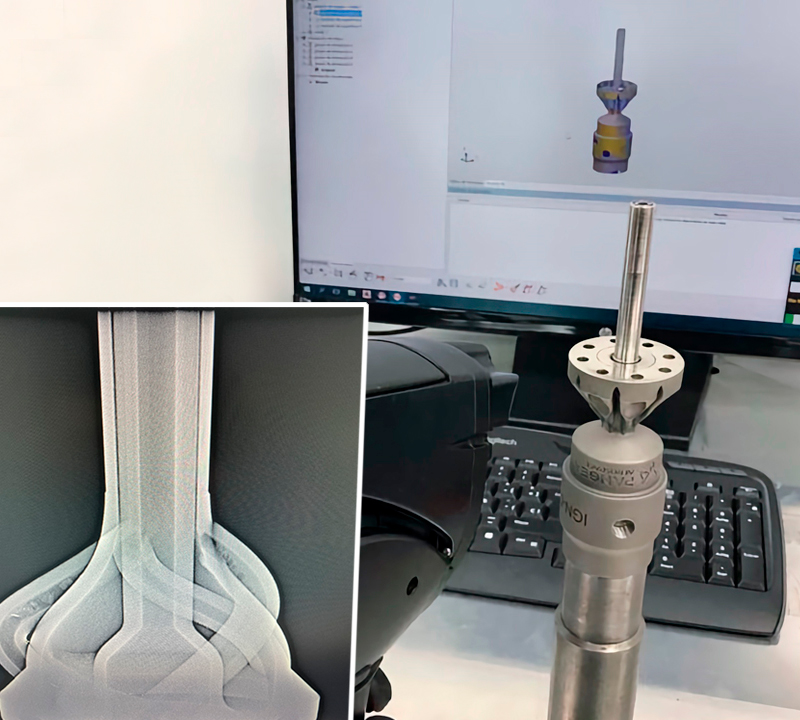

AENIUM CAD/CAE engineers will work alongside your team optimizing part geometry following:

Combined Lightness, heat/electrical transfer efficiency and load paths design with the highest reliability standards for your high-responsibility components you will step up.

Designing & certifying alloys for your application to achieve the highest functionality standards following your material needs. Our R&D team will support you in those cases when material science is critical.

Our portfolio in material science with complex alloys:

Best cost-effective industrializations come always along with fast ROIs, short lead times and high-reliability components.

Our application team will study your needs and parameterise all the steps on the industrialisation road for innovative certified affordable projects.

From our EOS certified parameters to our big portfolio of complex performance materials and optimized parameters. The material processing and performance is not an AM problem anymore.

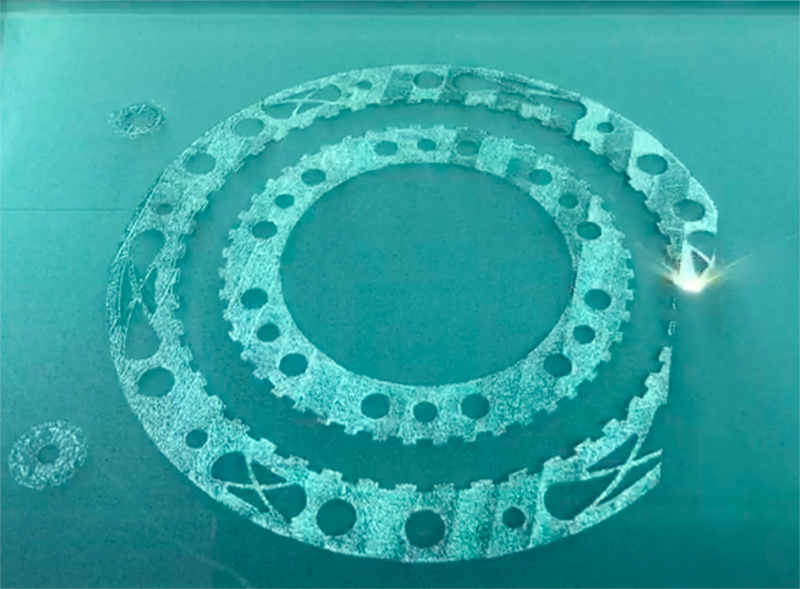

Following our extended experience over material science and LASER melting, our DMLS / SLS team work over LASER parameter for achieving high-performance results and avoiding crevice defects, internal stress concentration and to achieve the highest mechanical properties and microstructure desired.

From our EOS certified parameters to our big portfolio of complex performance materials and optimized parameters. The material processing and performance is not an AM problem anymore.

A new optimization world is now within reach. Through “Multivolume variable LASER energy density” we empower those pieces that require different mechanical properties or thermal/electrical behaviour over the same part, programming the microstructures and LASER CAM algorithm over it. Discover how our energy density patent improves your needs through the most complex AM approach to material engineering applied to your parts.

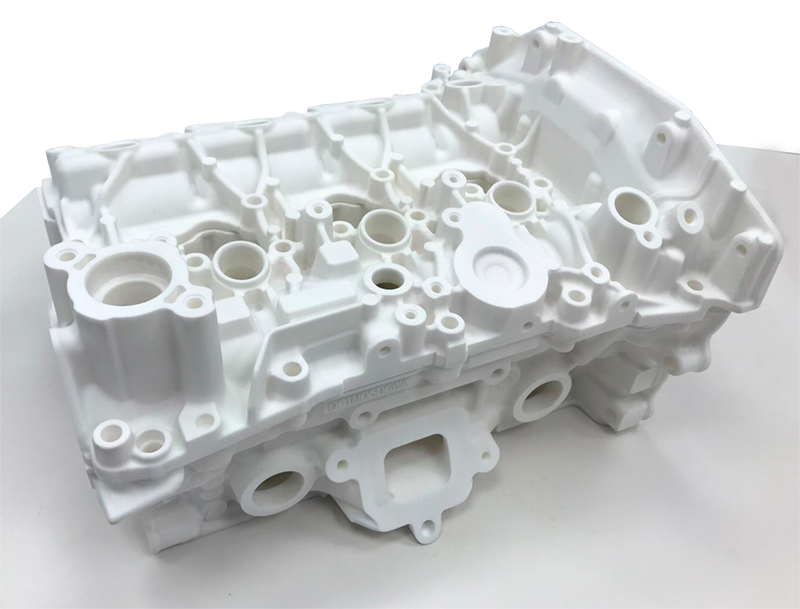

Metallurgy powder bed fusion DMLS through industrial equipment EOS M280-M290 under the best quality manufacturing standards. Risks of casting traditional problems and CAD limitations belong to the past.

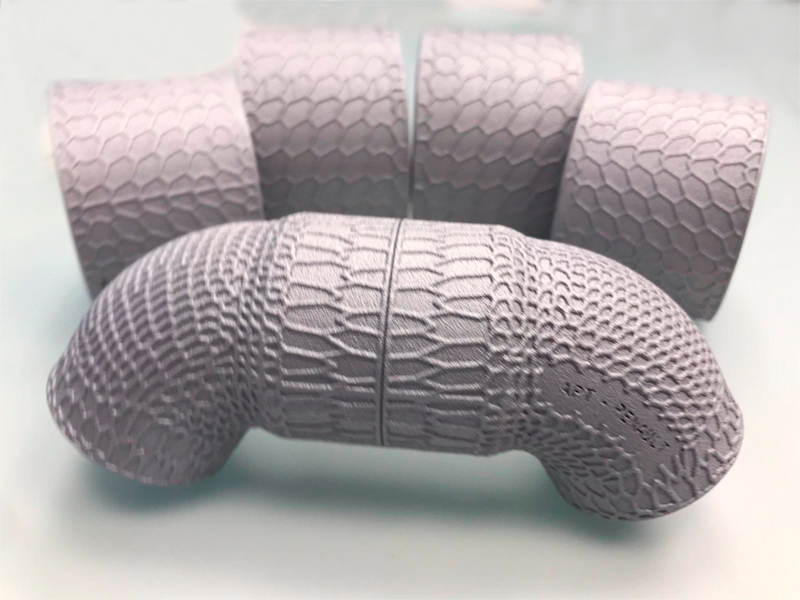

EOS – SLS industrial equipment under the best quality manufacturing standards. No more tooling investment for the production of your plastic parts.

As explained for metal we also work over polymeric powder analysis and additive with custom glass fiver (from 10% to 46.5%) for achieving high-performance behaviour over cryogenic applications, low TML outgassing limit for space field, high tensile strength and other mechanical properties.

Additive polymeric powders with ceramic nanoparticles ( Like ZnO-nPs) empower new thermal and electrical behaviour over technical polymers.

In-house bespoke Electronic/Thermal Nabertherm heat treatments, electrolytic coatings, Blasting, surface automatic RÖSLER micropolishing, 5.5 axis machining and EDM cutting. Electronic technical reports of Electronic Heat treatments on our ovens and HIP available.

Industrialising your production needs under the ASTM-NADCAP requirements. Reliability, innovation and cost-effectiveness never so close before.

Faro equipment for measurement certification.

AENIUM ENGINEERING S.L. has been a beneficiary of the European Regional Development Fund whose objective is to improve the competitiveness of SMEs and thanks to which it has launched an Action Plan with the aim of improving its positioning in foreign markets through the implementation of innovative solutions during the year 2021. For this, it has had the support of the InnoXport Program of the Chamber of Commerce of Valladolid and the Provincial Council of Valladolid.